| Purge Station |

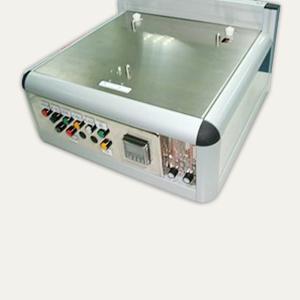

300mm Purge Station

|

|

|

|

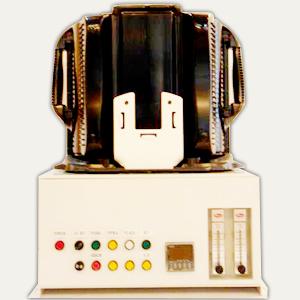

Purge Station:

Ø Process Yield Consistent, reliable, uniform interface layers for growth or deposition; Ensures process control.

Ø Defect control No moisture or AMCs to catalyze defects such as voltage threshold shifts, corrosion, voids, T- topping etc.

Ø Cycle time Process windows extended-no reworks; potentially less process steps (end-to-end processing).

Ø Tool Throughput Elimination of process steps and recipes e.g. high temp bakes, oxide breakthrough, or pre-cleans; shorter vacuum pump-down times.

Ø WIP Management Longer storage capabilities. |

|

|

Nitrogen Purge Application

Ø Stand alone type O2/RH is very critical from process to process Many IDM and DRAM doing now Ø Stocker /OHB embed unit (discontinue purge) Q time control Foundry customers Ø Continues purge in stocker Very tight control in RH Few IDM in USA |

|

.jpg)