| Purge Station |

Nitrogen Purge Benefit

|

Ø Consistent control of prepared surface from contaminations. Silicon Germanium

• DOME-shaped 250nm wide defects caused by dislocation nucleations in SiGe exitaxial layers in >13ppb H2O within the process gases. • Moisture at wafer surface would prevent proper growth and produce EPI-like defects.

Ø Prevent native oxidation growth at the interface and provide min of long bake-off process steps.

Epitaxial Deposition

|

|

• Poor control of the interstitial interface prior to EPI growth will produce Epitaxial defects. • Stacking default/Epi-spikes/Mound or hillock.

Ø Ø Better control of the interface will reduce implant variability and promote better control of later diffusion during RTP.

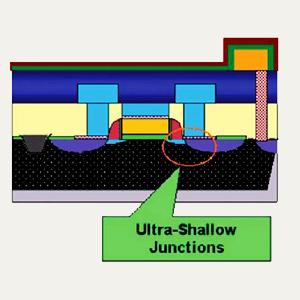

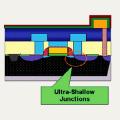

Ultra Shallow Junction

• Fast logic devices require extremely shallow junction with lower sheet resistance which in turns implies higher annealing temp Insert environment will prevent ambient doping of the source area |

|

Ø Storage solution between process steps

Copper Voids

• Moisture induces defects at the interface between the seed layer and electrochemical plating will create voids, excessive grain boundaries which can lead to Cu electro-migration, higher resistance and produce itself either as a infant mortality or in the filed as a catastrophic failure. |

|

Ø Elimination of the ambient catalysts and/or removal of adsorbed contamination will increase the margin of safety and process window.

Copper Corrosion

• Post CMP is highly susceptible to corrosion due to its Galvanic reaction with moisture, acids and light. • Bridging, shorts, electro migration and high resistance |

.jpg)