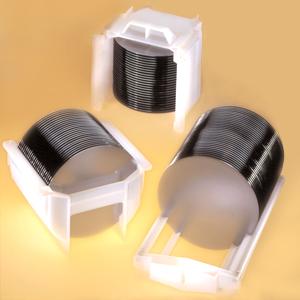

| 200mm Wafer Handling Systems |

Home

> Products > Entegris Micro Electronic Products > 200mm Wafer Handling Systems > 200mm Process Wafer Carriers200mm Process Wafer Carriers

Traditional molded PFA process wafer carriers and modular construction PFA process enhancement wafer carriers for wet chemical processing applications.

Process Enhancement Wafer Carriers

General Specifications

- Open flow carrier allows solutions to pass through evenly and quickly

- One-half the volume and mass of traditional process carriers

- One-fourth the surface area of traditional process carriers

- Modular construction includes reinforcement rods for added rigidity and strength

- Lift points on carrier ends for automated handling

- V-notch locators on carrier ends and rails forlocation on equipment

- Chemical resistant PFA material wetted surfaces

- Wafer capacity: 50

- Pocket spacing: 6.4mm (0.25")

Traditional Process Wafer Carriers

General Specifications

- Open side walls allow solutions to pass through evenly and quickly

- Low and high profile

- "H" bar for equipment interface

- Locating track notches at the center of the thirteenth pocket

- Pins and holes on the top rail (unless noted)

- Chemical resistant PFA material

- Wafer capacity: 25, 26 or 50

- D1 dimension: 25.4mm (1.00")

- Pocket spacing: A192-82M: 3.2mm (0.13")

All others: 6.4mm (0.25") - Pocket flat: 1.7mm (0.07")

Material Specifications

Natural PFA

- High purity process wafer carrier material

- Translucent perfluoroalkoxy (PFA)

- Temperature limits:

Continuous use (process enhancement): 165°C

Continuous use (traditional): 180°C

Wafer insertion: 250°C